About Polycut 500Pro

Developed by leading professionals from the Danish construction industry ContactDeveloped for the craftsman

Polycut 500 Pro has been developed to be used on construction sites by professional craftsmen.

The polystyrene cutter machine is robust enough to handle being used on the construction site and is easy to carry in the van.

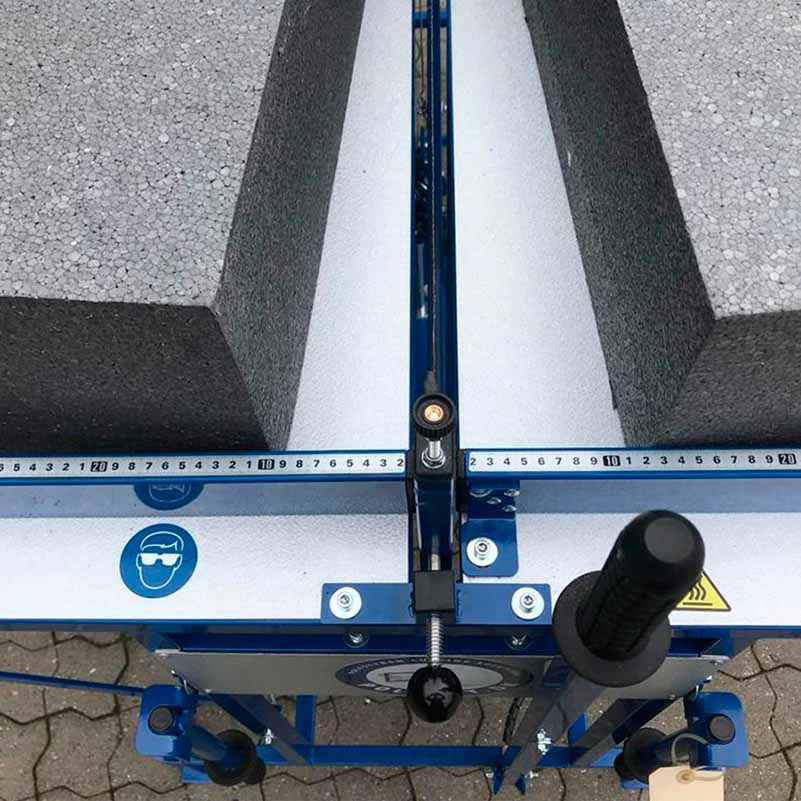

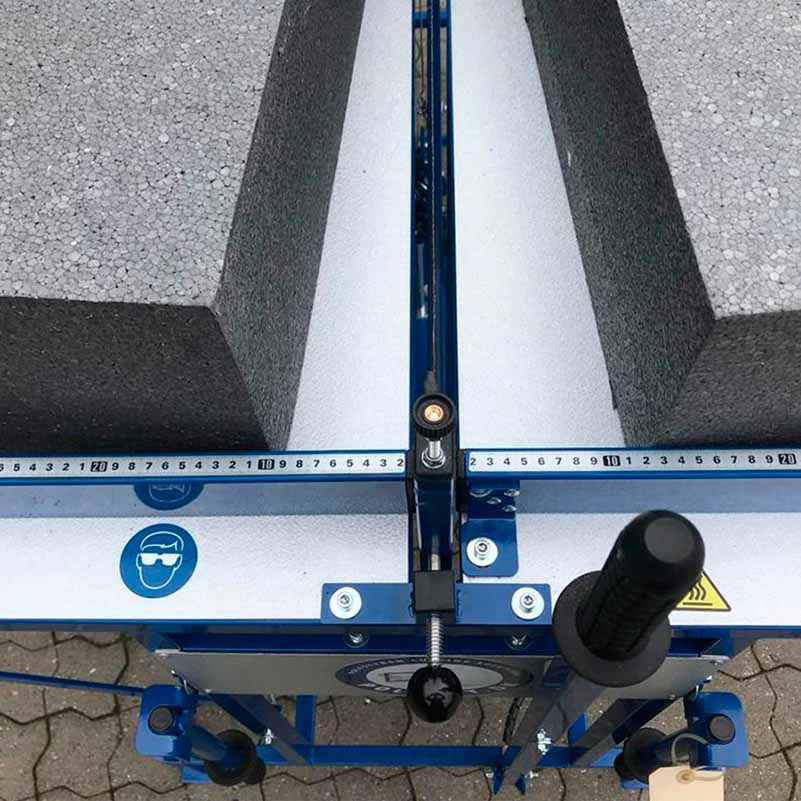

The machine has a fixed land with measuring units on both sides of the cutting wire, which makes it easy to measure out the polystyrene plate so that the cut is laid precisely.

Whether you need a neat vertical cut or a cut at up to a 45 degree angle, the Polycut 500 Pro cuts precisely and quickly.

The Polycut 500 Pro cuts using its own weight, ensuring a uniform cut that is always straight.

Developed and produced in Denmark

The Polycut flamingo cutter machine has been developed in collaboration with leading professionals from the Danish construction industry and is produced in Denmark.

The macine can cut up to 500 mm. polystyrene and can thus meet the requirements for insulation thicknesses in the construction industry.

Polycut was developed based on an idea from a major Danish contractor in collaboration with Mikael Rødkjær.

Mikael immediately started the development of the first Polycut Polystyrene cutting machine and now the sequel, Polycut 500 Pro, has come on the market.

It doesn’t really matter which tool you use to cut thick polystyrene plates, and with Polycut you have a reliable and precise machine.

Developed and produced in Denmark

The Polycut flamingo cutter machine has been developed in collaboration with leading professionals from the Danish construction industry and is produced in Denmark.

The macine can cut up to 500 mm. polystyrene and can thus meet the requirements for insulation thicknesses in the construction industry.

Polycut was developed based on an idea from a major Danish contractor in collaboration with Mikael Rødkjær.

Mikael immediately started the development of the first Polycut Polystyrene cutting machine and now the sequel, Polycut 500 Pro, has come on the market.

It doesn’t really matter which tool you use to cut thick polystyrene plates, and with Polycut you have a reliable and precise machine.

Easy, fast and accurate

The Polycut 500 Pro is quick and easy to operate, and with the table that can be folded down along the side of the machine and the 2 carrying handles, it is easy to get the machine into the van.

The folding table also ensures good support for the polystyrene plate, and on the fixed land there are measuring units on both sides of the cutting wire, which make it easy to find the desired measurement on the polystyrene.

The cutting wire cuts with its own weight and ensures a precise cut and at the same time it is fast.

If you need to have the polystyrene cut at a specific angle, this can also be done, simply by setting the desired number of degrees.

Would you like to solve your cutting tasks easier and faster than you have been able to before?

Then give Polycut 500 Pro a try.

Service program and spare parts

Polycut naturally maintains a full spare parts program for the Polycut 500 Pro, so that you do not end up in a situation where you cannot use your machine anymore.

You also have the option of signing a service contract when you buy your machine, which gives you the opportunity to avoid maintenance and replacement of spare parts.

We manage that for you.

Regardless if you sign a service agreement or not, you don’t need to fear that the machine requires a lot of maintenance.

It is made to be used, so what you have to do yourself will be minimal.

Service program and spare parts

Polycut naturally maintains a full spare parts program for the Polycut 500 Pro, so that you do not end up in a situation where you cannot use your machine anymore.

You also have the option of signing a service contract when you buy your machine, which gives you the opportunity to avoid maintenance and replacement of spare parts.

We manage that for you.

Regardless if you sign a service agreement or not, you don’t need to fear that the machine requires a lot of maintenance.

It is made to be used, so what you have to do yourself will be minimal.